Ronen® is a professional China Cold Heading Machine Manufacturers and China Cold Heading Machine suppliers. Ronen® has Fastener Cold Heading Machine core engineer and R&D team, with rich experience, with continuous innovation, the company meets the recognition of customers and operators. Has strict quality control system, ensuring machine quality, improving production efficiency and achieving the Win-Win Result.

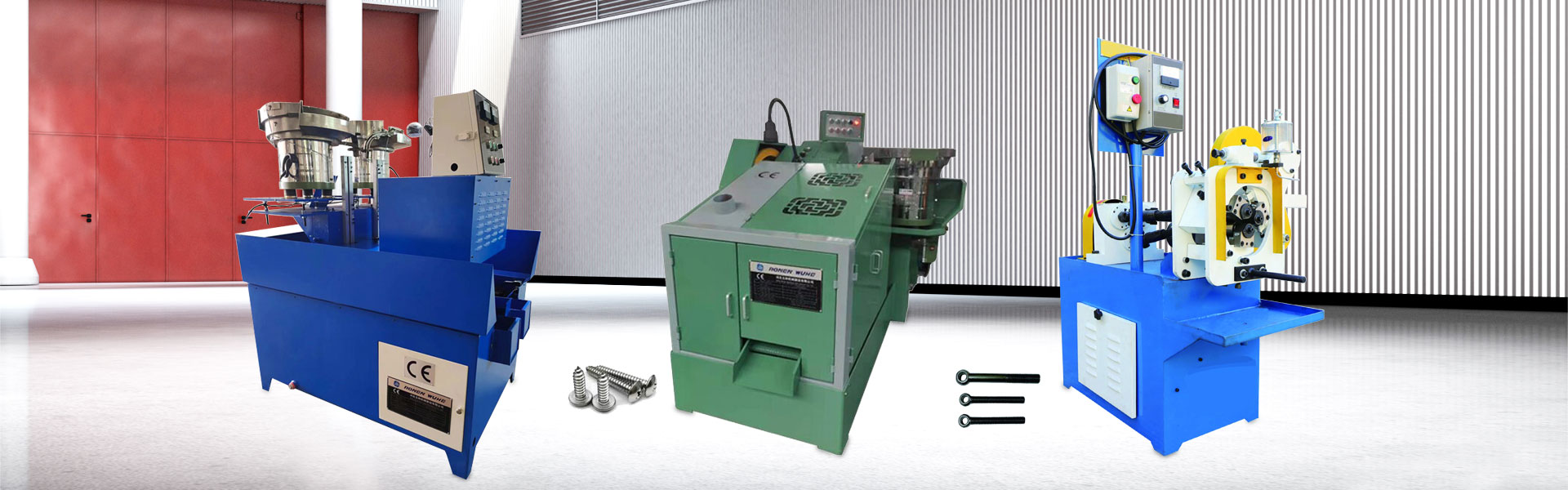

At present, the model ofRONEN have complete specifications, and can be customized according to customers’ finished products. Ronen® Cold Heading Machine is a specialized machine tool with high efficiency and automation among Cold Heading Machinery. Cold Heading Machine is used as an important means of producing different kinds of bolts, screws, rivets and nuts in the field ofFastener industry.

Because of the advantage of the Cold Heading Machine itself and the superiority ofCold Heading technique, the machines also are widely used in different national economic territories for producing fasteners and abnormal non-standard parts such as aviation, steamer, machinery, rail traffic, vehicle, motorcycle, bicycle, sewing machine, construction, furniture, light industry and daily necessities, etc. Ronen® Cold Heading Machine has big share in domestic market, and in recent years, we have exported to Europe, USA, Korea, Russia, India, Indonesia, Vietnam, etc.Has Taiwan Technology level engineers teams, and with strict technical monitoring and production process, the plant area is about 15000+ square meter. From product introduction, technical exchange to the whole process of product after-sales, will give you the most meticulous and thoughtful service, and strive to make the company into the domestic Cold Heading Machine industry first-class brand. We look forward to your presence and guidance!

Buy Factory Directly Supply Lock Nut Part Cold Heading Machine. RONEN MACHINERY is a nut former manufacturer and supplier in China. Lock Nut Part Cold Heading Machine is suitable for Auto-parts, Construction Fasteners, Bearing, Machinery, Electronics, Furniture, Transportation Industry, etc.

Professional China quality Slotted Screw Making Machine manufacturer and supplier in China. Adopts cold heading way to make the wire rod upsetting by double-click the whole mould form.Finished Feeding, straightening, cutting material, forming, discharging by one machine.

Slotted Screw Making Machine automatically processes, the wire into semi-finished products.

Hot sale quality Inner Square Screw Cold Forming Machine produced by Ronen® is suitable for auto parts, construction hardware, construction fasteners, machinery, electronics, etc. industrial fields , we have exported to Europe, USA, Korea, Russia, India, Indonesia, Vietnam etc. counties.

China Ronen® Locking Screw Forging Machine Factory Directly Supply. The machine is suitable for chipboard screws, drywall screws, self drilling screws, self tapping screws, wood screws, machine screws, furniture screws, electronic screws, precision screws, fasten piece used for car and motor car, nuts, spring washer, rivets, pin bolt and split pin, steel structure used rivets and fasten pieces, kinds of metal special-shaped pieces etc products’ upsetting and forming.

RONEN is Set Screw Cold Heading Machine manufacturers and suppliers in China. We can provide professional service and better price for you.

Set Screw Cold Heading Machine’s purpose is to the selected such as carbon steel, stainless steel, aluminum, copper and other metal wire, with appropriate mould, according to the allowable pressure wire than, under the effect of crankshaft connecting rod drive the slider, automated, fast after the required size of the wire will be automatically shear, extrusion in the mould for needed fastener head type, stem diameter, facilitate thread rolling, or become a qualified rivet type fastener. The heading machine automatically processes, the wire into semi-finished products.

Professional China quality Screw Cold Heading Machine Manufacturers and Suppliers. Machine Screw Cold Heading Machine adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding, straightening, cutting material, forming, discharging by one machine.